How to Press DTF Transfers: A Step-by-Step Guide for Hot and Cold Peel

Welcome to Transfer Print Center! In this blog post, we will guide you through pressing DTF (Direct-to-Film) transfers using both hot peel and cold peel methods. These methods ensure you achieve vibrant, durable, and professional-quality prints every time. Whether you’re a hobbyist or a business, our DTF transfers are designed to make your projects shine.

What Are DTF Transfers?

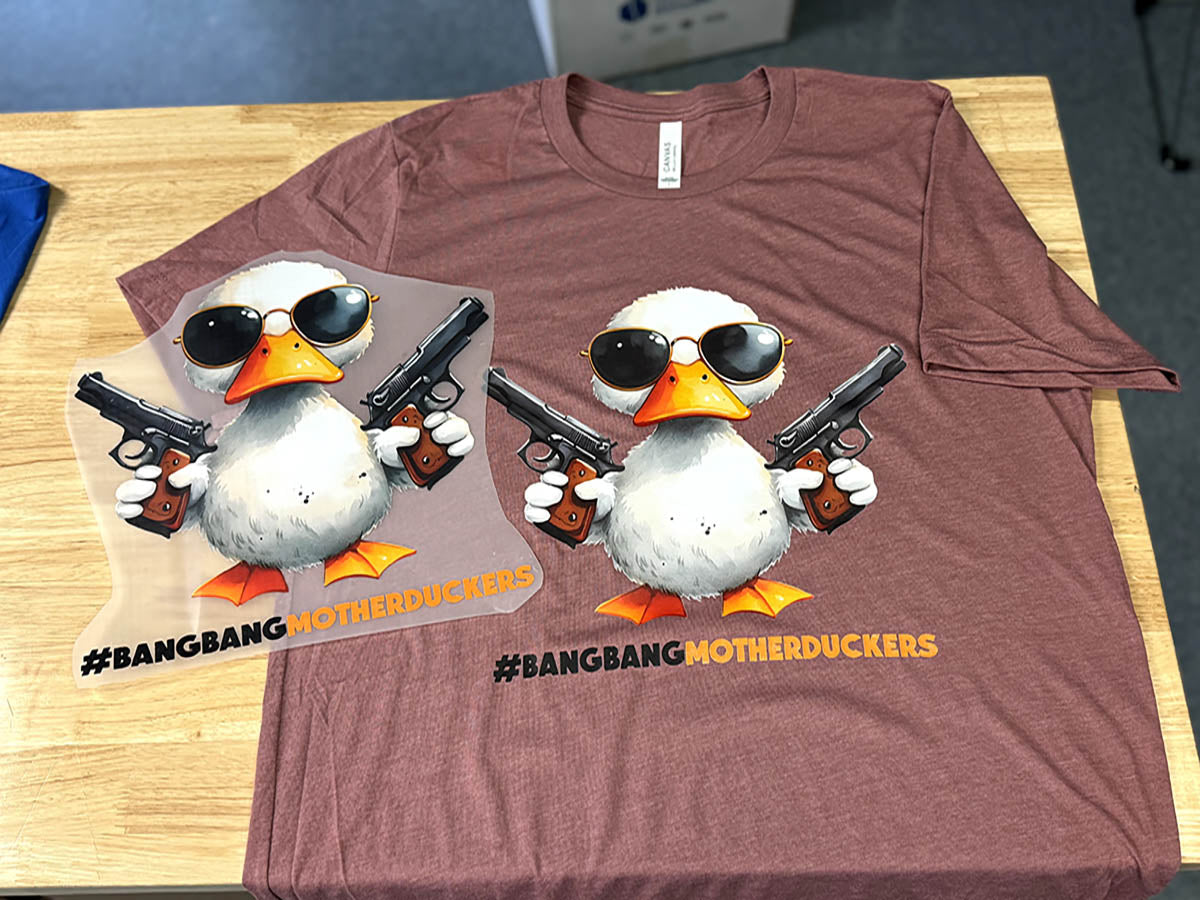

DTF transfers are a versatile printing method that allows you to transfer any design onto a variety of fabrics, including cotton, polyester, blends, and more. These transfers use special inks and adhesive powder to create detailed, vibrant, and long-lasting prints.

Step-by-Step Guide to Pressing DTF Transfers

1. Preparation

Materials Needed:

- DTF transfer sheet (available at Transfer Print Center)

- Heat press machine

- Teflon sheet or parchment paper

- Garment (e.g., t-shirt, hoodie)

2. Setting Up Your Heat Press

For Hot Peel Method:

- Temperature: Set your heat press to 315°F (157°C). This temperature ensures the adhesive powder melts properly and bonds with the fabric.

- Pressure: Adjust to medium-high pressure. Proper pressure ensures an even transfer and prevents peeling.Pressure:* Medium pressure (70 psi)

- Press Time: 6 seconds. This duration ensures the transfer adheres properly without damaging the fabric.

- Peel: After pressing for 6 seconds, immediately peel off the transfer film while it is still hot. This method allows the adhesive to bond quickly, producing a vibrant and sharp design.

- Repress: Press again for 6 seconds to ensure durability.

- Post-Pressing: Optionally, for extra durability, post-press the garment for an additional 5 seconds with a Teflon sheet on top.

For Cold Peel Method:

- Temperature: Set your heat press to 330°F (165°C). This temperature ensures the adhesive powder melts properly and bonds with the fabric.

- Pressure: Adjust to medium-high pressure. Proper pressure ensures an even transfer and prevents peeling.Pressure:* Medium pressure (70 psi)

- Press Time: 13 seconds. This duration is optimal for the transfer to adhere without damaging the fabric.

- Cooling: Allow the transfer to cool completely before peeling. This cooling period is crucial for the adhesive to set properly. Allow 10-15 minutes to cool.

- Peeling: Once cooled, peel off the transfer film gently. The design should now be perfectly adhered to the garment.

- Post-Pressing: For extra durability, post-press the garment for an additional 5 seconds with a Teflon sheet on top.

3. Positioning the Design

- Pre-Pressing: Optionally, pre-press the garment for 2-3 seconds to remove moisture and wrinkles, ensuring a smooth surface.

- Aligning the Transfer: Place the DTF transfer on the garment in the desired position. Use heat-resistant tape if necessary to keep the transfer in place.

4. Pressing the Transfer

- Cover with Teflon Sheet: Place a Teflon sheet or parchment paper over the transfer to protect it during pressing.

- Pressing: Lower the heat press and apply pressure for the specified time.

5. Tips for Best Results

- Testing: Always test on a sample fabric to ensure settings are optimal.

- Maintaining Equipment: Keep your heat press clean and regularly check pressure and temperature settings.

- Storing Transfers: Store DTF transfer sheets in a cool, dry place to maintain quality.

Why Choose Transfer Print Center?

At Transfer Print Center, we offer high-quality DTF transfers that provide:

- Unmatched Color Quality: Vibrant and detailed prints.

- Durability: Tested to last up to 60+ washes without cracking or fading.

- Ease of Use: Simple application process with no need for weeding or pretreatment.

By following these steps and using high-quality DTF transfers from Transfer Print Center, you can achieve professional-grade results for all your custom printing projects.

By Transfer Print center

in July 13,2024