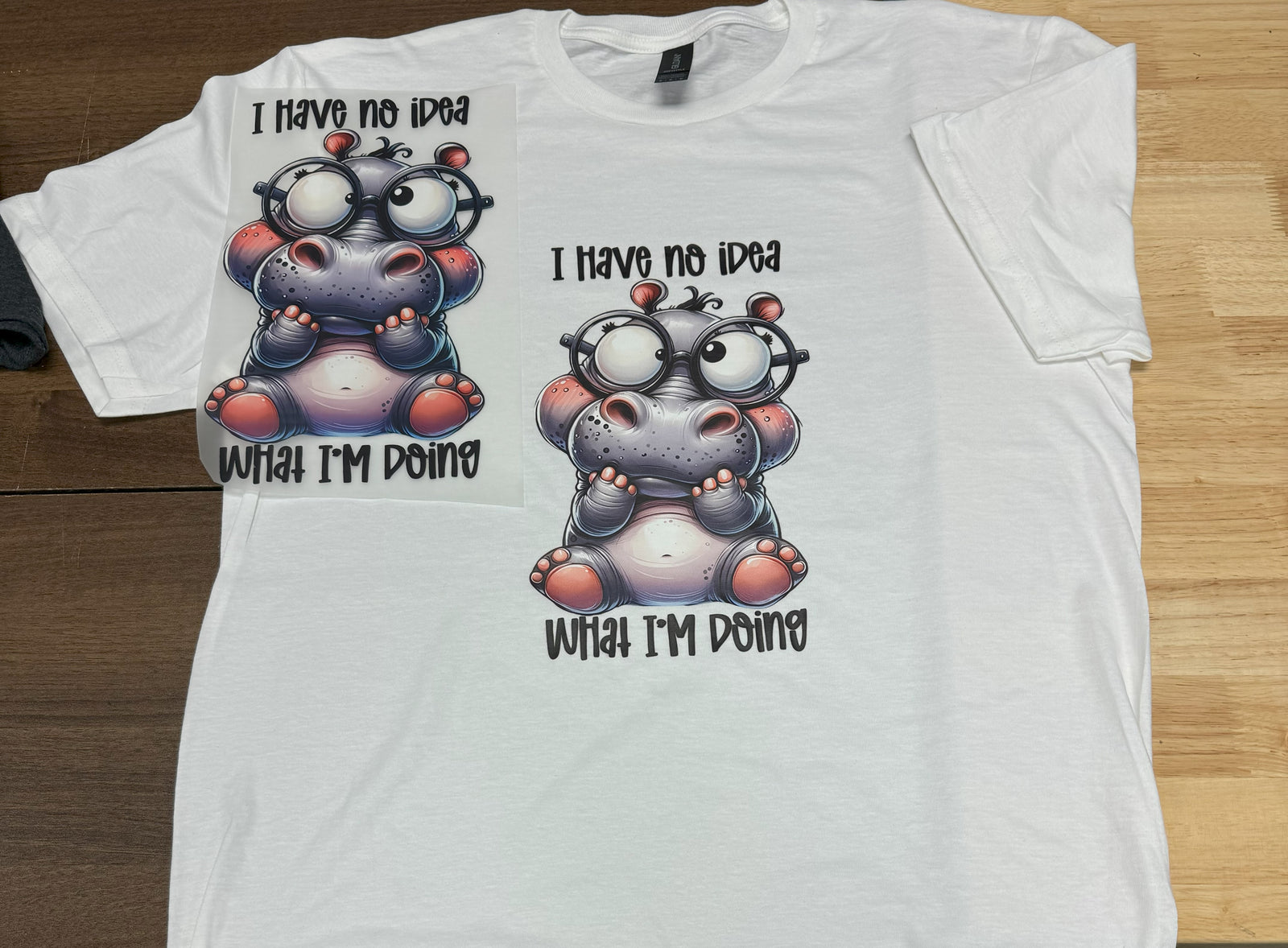

Achieve Vibrant, Durable, and High-Quality DTF Prints

Ensuring the highest quality for your Direct to Film (DTF) prints involves several key steps. Whether you're working on personal projects or running a business, following these guidelines will help you achieve sharp, vibrant, and durable prints every time. Here are some expert tips to improve your DTF print quality:

1. Use High-Resolution Images

- Resolution: Always use images with a resolution of at least 300 DPI (dots per inch). This ensures that the details are sharp and clear, and the prints do not appear pixelated.

- Dimensions: Ensure your image dimensions match the desired print size while maintaining the 300 DPI resolution. For instance, if you want to print an image at 12 inches by 8 inches, the image should be at least 3600 pixels by 2400 pixels (12 inches * 300 DPI = 3600 pixels and 8 inches * 300 DPI = 2400 pixels).

- File Format: Use lossless file formats like PNG, TIFF, or high-quality JPEG to preserve image details. Avoid formats that excessively compress the image, as they can cause a loss of detail.

2. Invest in High-Quality Printer and Inks

- High-Quality Printer: Use a high-quality DTF printer designed for this type of printing. Regular maintenance of the printer is crucial to avoid clogs and ensure consistent print quality.

- Premium Inks: Utilize high-quality DTF inks for vibrant colors and strong adhesion. Poor quality inks can lead to faded prints and reduced durability.

3. Choose the Right Film and Powder

- DTF Film: Use a compatible, high-quality DTF film with a good transfer rate that handles fine details well.

- Adhesive Powder: Apply a uniform layer of high-quality adhesive powder to ensure proper bonding of the ink to the fabric. Remove any excess powder to avoid clumping.

4. Follow Proper Curing Process

- Proper Curing Temperature: Set the curing temperature according to the manufacturer’s recommendations, typically between 160°C to 180°C.

- Adequate Curing Time: Ensure you cure the print for the recommended duration to prevent adhesion issues and enhance durability.

5. Prepare the Fabric Correctly

- Clean Fabric: Ensure the fabric is clean and free from dust, lint, or other contaminants that might affect adhesion.

- Pre-Treatment: Some fabrics may require pre-treatment to improve ink adhesion and print quality.

6. Apply Even Pressure During Heat Pressing

- Even Pressure: Apply even pressure across the entire print area during the heat pressing process to avoid incomplete transfers and poor print quality.

- Correct Pressure: Adjust the pressure settings on the heat press according to the fabric type and thickness.

7. Maintain a Controlled Environment

- Controlled Environment: Maintain a controlled environment for printing and curing. Temperature and humidity can affect print quality and adhesion.

8. Perform Regular Maintenance

- Printer Maintenance: Regularly clean and maintain your DTF printer to prevent clogs and ensure consistent print quality.

- Heat Press Maintenance: Ensure the heat press is calibrated and functioning correctly to provide consistent heat and pressure.

By following these expert tips, you can significantly improve the quality of your DTF prints, resulting in vibrant, durable, and high-quality products. Start implementing these practices today and see the difference in your DTF printing projects!

By Transfer Print center

in July 26,2024