Welcome to Transfer Print Center, your trusted source for high-quality DTF gang sheets, custom printing, heat press services, and more. As a leading provider in digital textile printing, we're excited to share our expertise on applying DTF (Direct to Film) transfers to achieve stunning, long-lasting results.

Understanding the Importance of Proper DTF Application

In today's dynamic world of custom apparel and merchandise, the demand for vibrant, durable, and personalized prints is at an all-time high. Direct to Film (DTF) technology has emerged as a game-changer, offering a versatile and efficient solution for businesses and individuals alike. By mastering the DTF application process, you can unlock the full potential of your custom designs and deliver exceptional products to your customers.

Preparing the Surface

The first step in the DTF application process is to ensure that the garment or substrate is properly prepared. This involves thoroughly cleaning and prepping the surface to create optimal conditions for the transfer to adhere. Depending on the material, specific cleaning agents or techniques may be needed to remove dirt, oils, or residues.

Once the surface is clean, choose the right heat press settings. Temperature, pressure, and time are critical factors that can impact the success of your DTF application. Refer to the manufacturer's guidelines or consult with our team to determine the optimal settings for your specific project.

Positioning the DTF Transfer

Proper positioning of the DTF transfer is crucial for a professional, seamless look. Carefully align the design on the garment or substrate, ensuring it is centered and straight. Secure the transfer in place using heat-resistant tape or a silicone pad to prevent shifting during the pressing process.

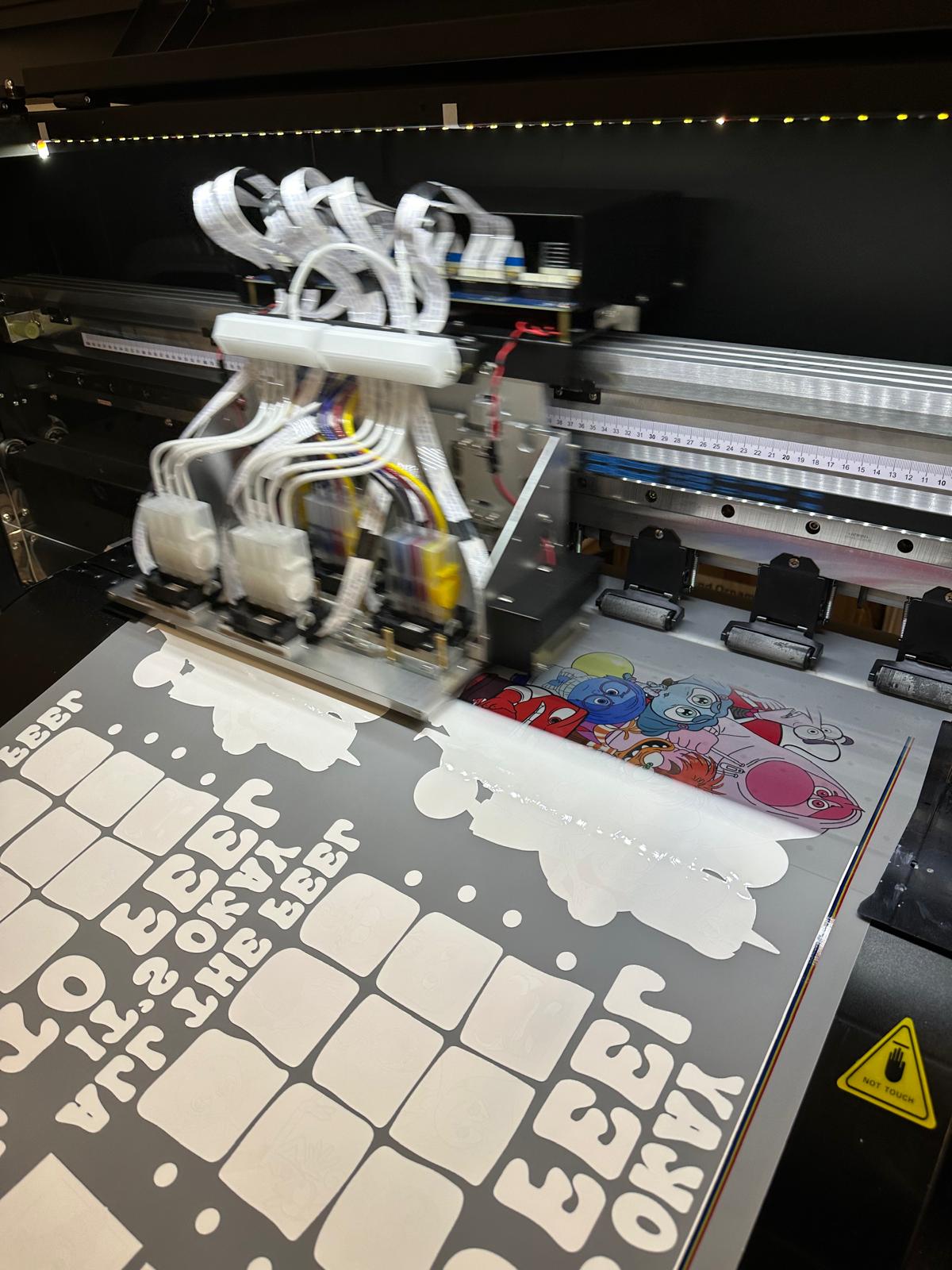

Heat Press Application

The heat press application is the heart of the DTF process. Follow the recommended temperature, pressure, and time guidelines to ensure a successful transfer. Applying the correct amount of heat and pressure is essential for the ink to properly adhere to the fabric or substrate.

During pressing, be mindful of hot spots or uneven heat distribution. Adjust the press as needed to ensure even coverage and consistent results. After the initial press, allow the garment or substrate to cool completely before removing the transfer liner.

Post-Application Care

Once the DTF transfer is applied, follow proper post-application care instructions. Allow the garment or substrate to cool completely before handling, as the heat can continue to affect the transfer. Additionally, provide your customers with washing guidelines to ensure the longevity of their custom prints.

Troubleshooting Common Issues

Despite your best efforts, you may encounter occasional challenges during the DTF application process. Common issues such as peeling, cracking, or faded prints can be addressed through proper troubleshooting. Consult our team or refer to manufacturer guidelines to identify and resolve any problems that may arise.

Conclusion

Mastering the DTF application process is the key to unlocking the full potential of your custom prints. By following the best practices outlined in this guide, you can deliver high-quality, durable, and visually stunning results that will impress your customers and set your business apart.

At Transfer Print Center, we're committed to providing you with the tools, resources, and support you need to succeed in digital textile printing. Visit us today to explore our selection of DTF gang sheets, custom printing services, and state-of-the-art heat press equipment. Together, let's elevate your custom printing game to new heights.